Your Trusted Provider of Drilling Motors and Accessories

MWD SYSTEMS

Nzone Guidance, has developed a strong team of people who are dedicated to maintaining a high standard of workmanship. The dedication and constant training makes Nzone stand out above the rest.

MWD systems, combined with the highest quality auxiliary components, are expertly integrated into compact, field-ready Kits. Nzone is committed to quality service and we are continuously expanding capabilities. Each standard kit contains 2 complete downhole and surface systems.

Our downhole tools include electronics, directional sensors, gamma probes, and pulsars, that are configurable and customizable to meet your specific needs. The probe can be deployed in standard non-magnetic drill collars and is fully retrievable and re-insertable.

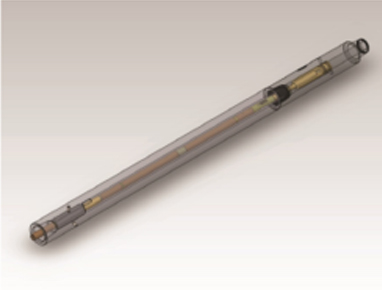

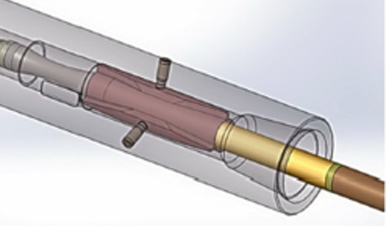

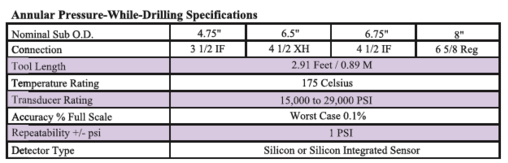

PWD

Annular Pressure-While-Drilling (APWD) sensor increases drilling efficiency by providing real-time down-hole pressure information that allows the driller to make faster and better decisions.

BENEFITS

- Real Time Pressure Monitoring.

- Fully Retrievable.

- Better Hole Cleaning Monitoring.

- Detecting Kicks and Influxes.

- Reduced Drilling Expenses.

- As Close to the Bit as Possible.

FEATURES

- Adapts to Conventional Mud Pulse Tool String.

- Memory Recordable.

- Equivalent Circulation Density (ECD) Measurements.

- Can be Logged to Most Gamma Software.

APPLICATIONS

- Reservoir Pressure Management.

- Drilling Optimization.

- Emproved ECD Management.

- Maintaining Tight Overbalance to Optimize ROP.

- Maintaining Tight Overbalance without Reducing Safety.

Mud Pulse System

Our modular Downhole Platform includes electronics, directional sensors, gamma probes, pulsers and battery packs that are configurable and customizable to meet your specific needs. The probe can be deployed in standard non-magnetic drill collars and is fully retrievable and reinsertable. Each Standard Kit contains two each of the following components:

- Directional Modules

- Battery Assemblies

- Gamma Sensors, 175 °C

- m+ Motor Pulser™

- Required Running Gear

Our Surface Systems include our industry-leading data acquisition, decoding and display technologies – advanced receivers, rugged displays, transducers, wireless systems, feature-rich software and web-based services – all designed to seamlessly integrate your devices and data.

Each Standard Kit contains two each of the following components:

- BTR-W™ Receiver System Kits

- RD-G Rig Display

- Wireless Kit

- Pressure Transducers

- Support Cables